Aprés la moto ...

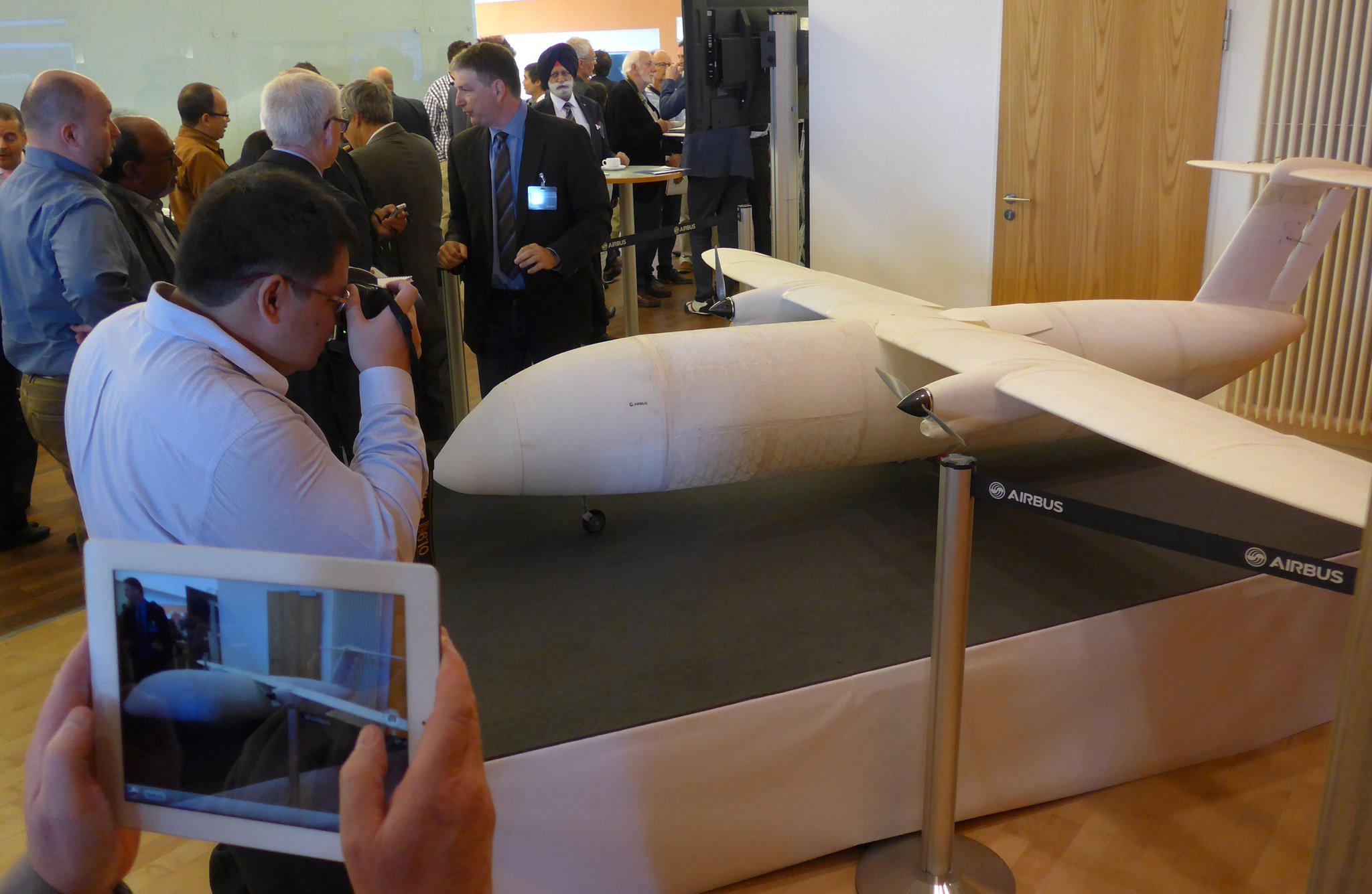

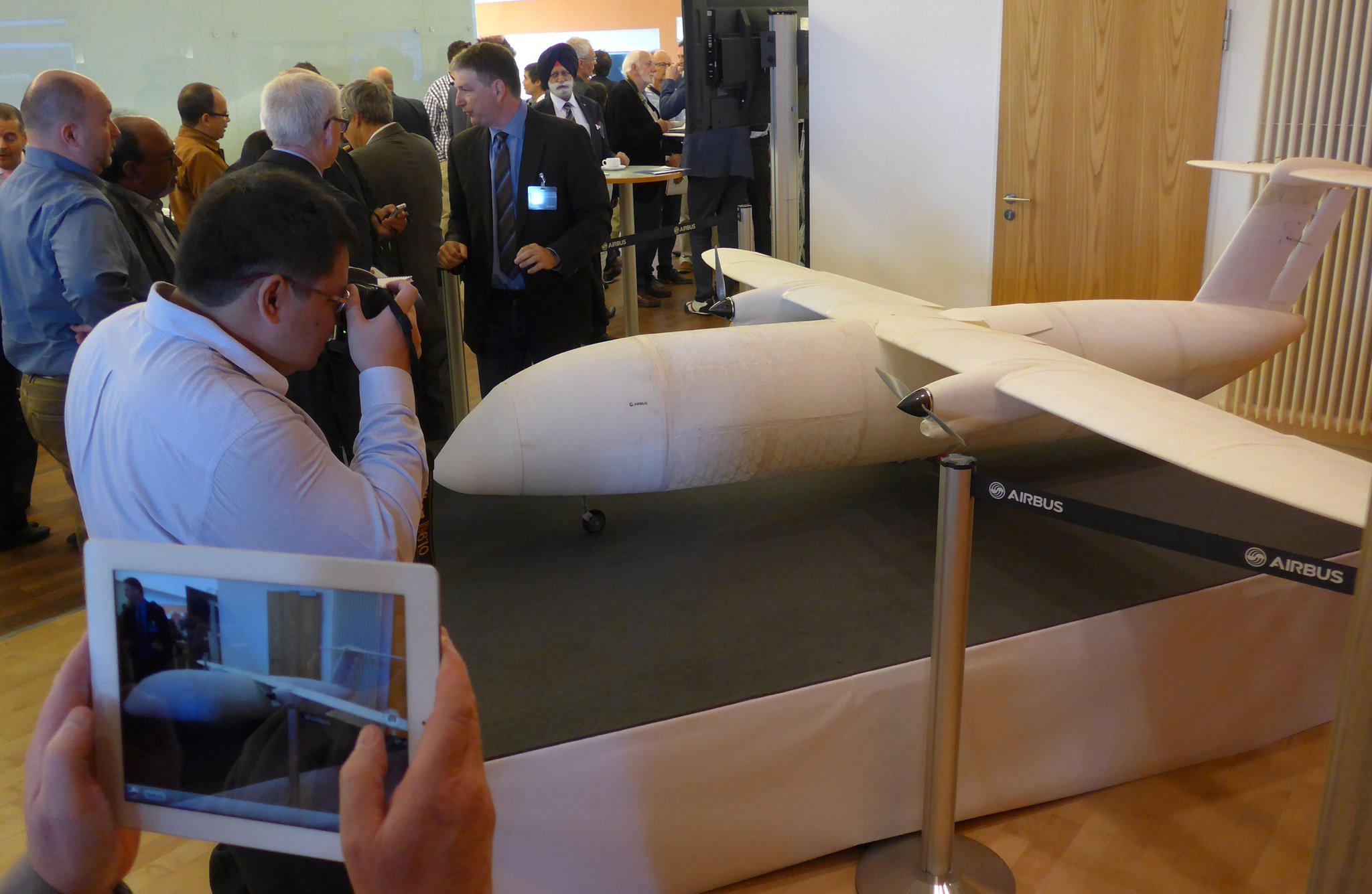

L'avion imprimé 3D chez Airbus (On en reparlera ...)

Et pas en une seule pièce, des morceaux de 40-50 cm !

Une maquette de 4m pour commencer, un petit bi électrique !!

Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités Airbus Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités Airbuswsj, accès payant apparemment ?Beochien a écrit:J'ajoute le WSJ, un commentaire de Robert Wall, pour la production des A350.

Ils s'intéresse en particulier aux possibles retards du A350-1000, alors, 2-3 mois ou 6 mois ??

http://www.wsj.com/articles/new-airbus-airliner-facing-delays-at-critical-time-1466004793

Re: Actualités Airbus

Re: Actualités Airbus Re: Actualités Airbus

Re: Actualités Airbus Re: Actualités Airbus

Re: Actualités Airbus Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités Airbus Re: Actualités Airbus

Re: Actualités Airbus Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités AirbusFB n'a pas évité l'A380, la partie de l'article correspondante est relativement importante, mais je ne l'ai pas reprise car elle n'apporte pas grd chose (de nouveau) selon moi.Beochien a écrit:Conclusion méchante ...

Pas de vrai nouvel avion avant 2030 ... c'est loin ...Et 15 ans sans nouveau modèle ... hum !

Le B777-9, est trop gros, un lancement désespéré de Boeing, pour garder le CASM compétitif vs le A351, alors, à quoi sert le A380 soigneusement évité dans l'article ... plus d'actualité ?

Bon, FB fait son boulot ... et met JL au pied du mur comme d'hab ...

Amener d'abord des clients et des intentions, pour un stretch d'A350.

Pas évident, avec le Golfe qui a fait le plein de B-777-9

Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités Airbus Re: Actualités Airbus

Re: Actualités Airbus Re: Actualités Airbus

Re: Actualités Airbus Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités Airbus

A300

A310 816

A320 12,830

A330

A340

A350 XWB 2,824

A380 319

Orders as of 31 August 2016 16,789

The month in review: August 2016

Airbus logged 144 bookings during August for its best-selling A320 jetliner families in both the New Engine Option (NEO) and Current Engine Option (CEO) versions, while the 61 aircraft deliveries from its A320, A330, A350 XWB and A380 product lines marked a record volume for a month of August.

Leading the new business was AirAsia’s order for 100 A321neo jetliners, finalising an agreement announced at the Farnborough Airshow during July. This is AirAsia’s first acquisition of the A320 Family’s longest-fuselage version, and it brings the carrier’s total orders for Airbus single-aisle aircraft to 575.

Also included in the August transactions were 10 A320neo jetliners for international lessor AerCap, along with order conversions involving five A320neo versions for Tunisair and one A321neo for Avianca. Increasing its orders for the A321ceo was global leasing company BOC Aviation, acquiring five more; while bookings for undisclosed customers involved 11 A320ceo and nine A320neo aircraft for one customer, along with three A320ceo jetliners for another.

With the new business in August, total orders for NEO versions of the A320 Family now stand at nearly 4,800 from 87 customers.

Taking the month’s cancellations into account, Airbus net orders for 2016 totalled 438 aircraft through 31 August (composed of 83 A320/A321ceo versions, 288 A319/A320/A321neo jetliners, 20 A330ceo and 14 A330neo aircraft, and 33 A350 XWBs).

The sustained delivery pace in August saw Airbus providing 47 A320 Family single-aisle aircraft (including the initial A320neo to LATAM Airlines Group). Widebody deliveries were composed of seven A330s (of which three were the world’s first A330-300 Regional versions, all received by Saudi Arabian Airlines), six A350 XWBs (involving the first for Thai Airways International, along with two for Cathay Pacific, and one each for Ethiopian, Qatar Airways and Singapore Airlines), and one A380 for Emirates.

Deliveries in August brought to 400 the total number of jetliners provided by Airbus to 70 customers during the first eight months of 2016.

Taking this latest order and delivery activity into account, Airbus’ overall backlog totalled 6,869 aircraft as of 31 August.

Re: Actualités Airbus

Re: Actualités Airbus Re: Actualités Airbus

Re: Actualités Airbus Re: Actualités Airbus

Re: Actualités Airbus Re: Actualités Airbus

Re: Actualités Airbus Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités Airbus

Re: Actualités Airbus Re: Actualités Airbus

Re: Actualités Airbus

For the first time Airbus can investigate cabin noise and vibrations using an 8.5-metre-long fuselage demonstrator representing an A320 fuselage segment, while significantly shortening the development cycle for new solutions. The new test platform at the Centre for Applied Aviation Research (ZAL) in Hamburg was established to help facilitate future advances in cabin noise reduction, without having to resort to expensive flight testing. The acoustic chamber also offers engineers the opportunity to perform detailed comparisons between simulation models and real-world physics, thus allowing better noise transfer predictions. The demonstrator can be subjected to sound waves around its full circumference via a system of 128 individually controllable speakers – a setup which was devised to replicate engine noise from existing and future propulsion concepts. By accurately reproducing conditions which apply in flight, the acoustic lab will allow Airbus’ interior noise teams to pinpoint where noise enters the cabin and how it is spread and transmitted. They then can explore how background noise can be reduced. The ZAL chamber can accommodate fuselage demonstrators of up to eight metres high and 15 metres long, including for Airbus’ A350 XWB and A330 widebody aircraft. The initial A320 fuselage mock-up is being thoroughly investigated before work begins on representative cabin interior components. Tests with passengers also are planned in the acoustic lab’s future.

Re: Actualités Airbus

Re: Actualités Airbus