Petit doublon

http://www.flightglobal.com/blogs/flightblogger/2009/09/breaking-boeing-charleston-vot.html

L'usine de Boeing Charleston se "désyndique"

C.f. fil dans Actualités des Industriels/Boeing

Bonne journée à tous

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1) Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1) Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

Getting Oriented: Where's the 787 fleet? Part Two

A somewhat rare Sunday post for me, but I thought it was a good chance to get oriented once again on the whereabouts of the 787 fleet.

ZA001 remains in Paint Hangar 45-04 where it has been since late July for side of body modifications. ZA002 was moved on Friday to the 48,375 square foot temporary structure ahead of its modifications as well, with ZA004 making the trip south to Aviation Technical Services (ATS) on Wednesday for the same purpose. If this order is any indication, the first, second and fourth 787s will likely fly in that order as well.

ZA003, still unpainted with a red Northwest rudder, is parked along side ZA005 in Building 40-24 (below) behind a China Southern 777-200LRF. ZA006 is all buttoned up in storage on the flightline and will head to ATS next.

The ZA designations, which were originally meant to run sequentially early into the production run, were changed when the delivery order for the early 787s were reassigned to All Nippon Airways. As a result, ZA007, the seventh production 787 became ZA100. However, the ZA numbers no longer run sequentially. ZA100 through ZA102 represent Dreamliners Seven through Nine, while Dreamliner 10 is designated ZA104 and Dreamliner 11 is ZA103. Confusing things further, Dreamliner 12 is ZA105 and Dreamliner 13 is ZA115.

The first production 787s are all positioned inside Building 40-26 (top) with ZA100 at position three, ZA101 at position two and ZA102 at position one in the body join tooling. The line is expected to pulse in the middle of next week to make way for assembly of Dreamliner 10/ZA104. The aft fuselage and wings for ZA104 have been in the factory since each arrived on August 31st and September 1st, respectively.

ZA100 now sits at the head of the 787 final assembly line, with ZA101 at position three and ZA102 in the body join tooling at position one. Both ZA101 and ZA102 have yet to receive their vertical tails yet.

As last reported, ZY998, the fatigue test airframe, remains on the 747 line in Building 40-24 just in front of the first 747-8F. ZY997 is being prepped for the side of body fix in Building 40-23 where the aircraft has been since April 2008.

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)http://www.flightglobal.com/blogs/flightblogger/2009/09/sources-boeing-to-begin-za001.htmlBoeing is set to begin installation of the side-of-body fix on ZA001 next week to return full static strength to the wing of the first 787, according to program sources.

Boeing declined to confirm the timing of the installation.

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1) Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)http://www.reuters.com/article/ousivMolt/idUSTRE58L4CS20090922?pageNumber=2&virtualBrandChannel=0&sp=trueBoeing 787 delays cast hard light on outsourcing

CHICAGO (Reuters) - Commercial airline customers are accustomed to flight delays -- but two years?

That's how overdue Boeing Co's revolutionary 787 Dreamliner is, and the meter is still running. The company says it plans to fly the fuel-efficient aircraft by the end of the year and has staked its credibility on the claim.

The 787 has a record number of orders and a design seen as a "game-changer" for the commercial airplane industry. But it is also the product of an unusual confederation of manufacturers from around the world.

In some ways, the 787 project tests the wisdom of heavy reliance on outsourced labor. Boeing, the world's No. 2 plane maker behind EADS unit Airbus, hopes the 787 validates a strategy that sent an unprecedented amount of work overseas to foreign suppliers.

The Chicago company turned to its suppliers much earlier in the development process than usual to tap in to foreign ingenuity and cut costs. They helped the plane maker create and understand technologies and provided additional development, design and manufacturing funding of their own.

Boeing's bumpy road to rolling out the Dreamliner was pockmarked with several glitches in the supply chain including problems with parts and software.

The most recent delay, announced in June, ruffled the feathers of Wall Street analysts and left Boeing scrambling to repair its credibility.

Even as the company gears up for the test flight, it now acknowledges that it outsourced too much of the 787 -- now six years in the making -- and will conduct its global partnerships differently in the future.

"We wouldn't do it exactly the same way," Boeing Chief Executive Jim McNerney said at an investor conference this month. "There's plenty of blame to go around. It's not just our suppliers' fault. It's equally our fault in many cases."

"I would draw the lines in a different place," he said. "I'd have more shared engineering done together. I would certainly have visibility on the supply chain across corporate boundaries. But I would still have the same supplier/partner concept."

Some experts, union leaders and even employees believe the company took a wrong turn when it developed its global partnerships.

In a September 10 letter to Boeing senior executives, Brian Norris, a technical designer working on contract at Boeing on the 747-8I program, challenged the company's outsourcing.

"Everyone that works for Boeing knows that poor management decisions, poor planning and leadership, and last but not least outsourcing have delayed the 787 program," he wrote.

Norris, whose contract position with Boeing ends in December, encouraged Boeing to bring more work to the United States, a move that could lure more U.S. military contracts.

A GIANT GLOBALIZED PUZZLE

The Dreamliner is already famous for its innovative design, which uses lighter, more durable composite materials and promises huge savings in fuel and maintenance costs.

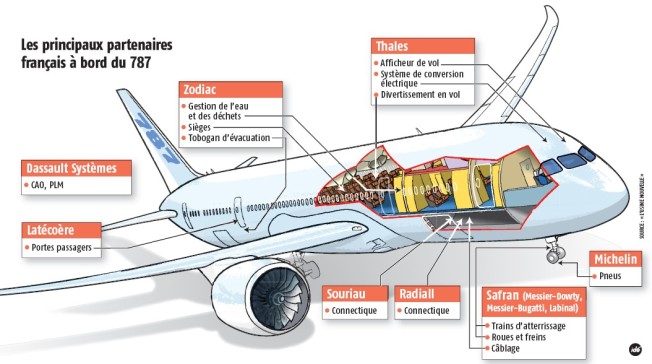

Boeing says its Dreamliner team has about 50 suppliers from the United States and around the world. The partnership features six companies from Japan, six from Britain, five from France, two from Germany, two from Sweden, and one each from South Korea and Italy.

They make sections of the fuselage, landing gear, parts of the wing, pumps, valves, engines, brakes, doors, waste systems escape slides, tires, tubing, cabin lighting and ducts.

Boeing uses three 747-400 cargo planes called Dreamlifters to retrieve the completed components from the suppliers and deliver them to its assembly plant in Everett, Washington.

Boeing has used the Dreamlifters since 2006. In that time the price of oil has doubled to nearly $150 a barrel, plummeted below $50, and is now back around $70, playing havoc with jet fuel costs and budgets.

Since Boeing began work on the Dreamliner in 2003, the supply chain has had glitches. The company announced the first of five delays to its delivery date in September 2007, blaming a shortage of bolts and problems with flight control software.

Subsequent delays also have been linked to problems with suppliers, slow assembly and a strike by its own employees that shut down Seattle-area plants for 58 days in 2008.

The most recent delay resulted from a structural problem in the area that connects the wing to the fuselage. In August, Boeing said an Italian supplier had stopped production in June on two sections of the fuselage due to structural issues.

Boeing still has a record 850 orders for the 787 on the books, even after customers have canceled orders for 73 of the planes. Boeing and the airline customers have remained mostly quiet about the cancellations. The weak world economy and financial problems for carriers are behind some, analysts say.

But Tom Wroblewski, president of the International Association of Machinists union, believes outsourcing remains the root of the problems that have plagued the 787 program.

"It's no surprise, at least to us, that this production system that they used on the 787 is a failure. That's what we warned the company about from the beginning," Wroblewski, whose union represents 45,000 active, retired and laid-off Boeing workers in Washington state, told Reuters.

"They still appear committed to this production system. They say they need to make changes," he said. "Well, I hope they've learned from those mistakes."

(Reporting by Kyle Peterson, Editing by Peter Bohan and Matthew Lewis)

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1) PARIS, 24 septembre (Reuters) - Oman Air décidera de conserver ou d'annuler une commande de six Boeing 787 Dreamliners une fois que le nouvel avion du groupe américain aura effectué son premier vol, a déclaré jeudi le directeur général de la compagnie aérienne. Boeing < BOEING CO > pense effectuer le premier vol du 787 d'ici la fin 2009 après deux années de retard. "Je pense que nous prendrons une décision une fois qu'il aura volé. Attendons de voir quand il volera", a déclaré le directeur général d'Oma Air Peter Hill à Reuters. Selon lui, Boeing est en train de perdre de sa crédibilité en raison des retards. Il estime que le constructeur aéronautique ne tient pas ses clients suffisamment informés. "Il faut s'inquiéter de la capacité de Boeing à livrer cet appareil comme il était conçu à l'origine. Mes prédécesseurs l'ont acheté sur la base d'une série de garanties de performance et de dates de livraison. Pour l'instant, Boeing n'a pas démontré que la confiance que nous avons mise en lui ne sera pas déçue dans un proche avenir", a déclaré Peter Hill. http://www.boursorama.com/infos/actualites/detail_actu_societes.phtml?num=3abf370e1c98f264fd55c5011b25499d |

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

787 update Sep 23

Posted by Guy Norris at 9/23/2009 7:38 PM CDT

Boeing has updated the status of the 787 side-of-body modification program and is conducting some pre-flight test work on ZA003 while preparing for the structural upgrade work to get underway. In his blog, BCA marketing vice president Randy Tinseth says Boeing has begun “mounting new fittings at stringer attachment locations within the joint where the wing attaches to the fuselage.” Modification work has begun first on ZA001 and the static test airframe, ZY997 (see below). ZA001 is enclosed in the paint hangar, ZA002 is in the temporary structure on the flight line, ZA003 and ZA005 are “using open space” in the factory and ZA004 and ZA006 are at Aviation Technical Services by the southern end of Paine Field.

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1) Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1) Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

The next major block point for Spirit will be at Airplane 34 with the incorporation of two major weight saving initiatives. The floor beams will transition to a hybrid titanium-sine wave design and a Pi-box shaped design for the seat tracks. These two changes, which will run the length of the fuselage, are expected to reduce the empty weight of 787 by more than 1000 lbs, according to the assessment found in Airbus's 787 Lessons Learnt dossier.

After the Airplane 34 blockpoint change, the next major change incorporation point for the 787 will be on the 787-9 at Airplane 109, says Leslie. Spirit expects to be able to use a mostly common set of tooling, as the stretch of the fuselage will come entirely in the center fuselage in Sections 43 and 46, not the forward Section 41.

"Right now, that's pretty big for us if we can keep the -8 and the -9 common," says Buck Buchanan. "When I say keep it common, that doesn't mean that the -9 has to look exactly like the -8 does today. But if we have to strengthen the 9 somewhere, if we can allow the 8 to carry the weight of the strengthening, we'd like to build one 41 section for the -8 and the -9. That has good cost benefits for the program. Every model we are that way, we did that on aluminum airplanes too. We really drive towards as much commonality as possible," he adds.

Buchanan says he expects the major sizing of the 787-9 to firm up about a year from now, but adds that the -9 configuration could be driven by what Boeing learns in flight test on the 787-8.

Boeing added an additional 21 airplane -8 buffer into the production stream, versus the previous plan to build the -9 at Airplane 88, according to program sources. The 787-9 is now set to enter service at the end of 2013, the same year that Boeing is planning to meet its 10 ship set per month ramp up.

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1) Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1) Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

Albaugh Visits Charleston

Newly minted President and CEO of Boeing Commercial Airplanes, Jim Albaugh, made his first visit to Boeing Charleston and Global Aeronautica today as news spreads of the recently filed permits for the second 787 assembly line.

Though there appears to be no direct connection to Albaugh's visit to Charleston and the selection of a second line, that decision - expected by year's end - will define his early months at the helm of BCA.

The Charleston Post Courier reports that the details of the permits make way for a 720,000 sq. ft. facility at the southern end of Charleston Air Force base on the Boeing Campus. Scott Hamilton notes that the Everett factory is 4.3 million sq. ft. by comparison. A quick calculation shows that 720,000 sq. ft. is roughly one-sixth of the Everett factory, which is split into six main bays for final assembly of the 747, 767, 777 and 787. The 720,000 sq. ft. figure makes the new facility's footprint almost identical to that of the current 787 line.

Sources indicate that that there has been increased surveying activity at the Boeing Charleston site with heavy equipment arriving on site, such as an excavator, steam shovel, small bulldozer and a brush cutter.

Boeing emphasizes that no decision has been made on the location of the second line, however, the permits indicate that brush clearing would begin in November if the green-light is given.

In addition, the State of Washington has publicly made its own case for why it should be the site of the second 787 line. Scott Hamilton explores the important difference between Washington State not providing Boeing any incentive for the second line vs. Boeing not actually asking for anything from Washington.

Z18 Moves -9 Again

This page reported last week that the first 787-9 would be airplane 109 instead of 88. The 109 figure was correct, however only to the Z17 schedule, not the latest Z18 revision, which now puts the first 787-9 at LN139. Apologies for any confusion.

The Changing Tone of the Backlog

In recent weeks, the tone of the now 840 aircraft 787 backlog has shifted. When early customers discussed cancellations, the reasons given were attributable to the economic downturn. QANTAS, LCAL, S7, SkyPeace, RBS (unconfirmed) all cited the economy as the key driver for the cancellations. Earlier this week, TUI Travel, which recently merged with First Choice, reduced its combined 787 order by 10, while expanding purchase rights for an addition 13 aircraft.

However, as the global recession begins to bottom, 787 customers have begun to cite the program delays as a driver in future fleet planning. Oman Air now says its order for 10 hinges on the outcome of first flight, while Kenya Airways is openly discussing a potential A330 order for interim capacity and LOT Polish Airlines is considering placing an Airbus order as well. In addition, Vietnam Airlines is also weighing its options on its 787 order.

First flight could help to settle much of this uneasiness, however the number of airlines seeking either interim lift or discussing potential order cancellations has grown considerably. These four airlines hold firm orders for a total of 39 787s, according to Boeing's website.

Dreamliner Eleven

Boeing is set to take delivery of the final structural sections ( Forward and Center) for the 11th 787 this weekend and early next week as the production pace beings to quicken. Early next week will also see the arrival of the wings for Dreamliner 12 as the line pulses forward. As the final body join for the 11th 787 gets underway later next week, the first production 787 (ZA100) will likely move out of final assembly to the paint hangar for closeout and aqueous wash of the wing tanks before receiving the official ANA colors. Access to the side of body and center tanks will still be available to install the wing fix later on.

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

787 - first signs of life?

Posted by Guy Norris at 10/7/2009 3:45 PM CDT

Boeing flight test personnel have returned to work on the first 787, ZA001, even while structural work continues to beef-up the wing to side-of-body junction that forced the company to postpone first flight in late June.

The activity is the first external sign of ‘life’ returning to ZA001 noted by this writer since taxi tests ended in July, and comes as Boeing moves the first production configured airframe (ZA100) off the assembly line. Tests on ZA001 are believed to be focusing today on the performance of the Honeywell-developed air speed system, and specifically the ‘lag’ between the data arriving from the static and pitot pressure ports and the airspeed display after processing by the air data computer.

The restart of systems testing on ZA001 is viewed as an optimistic sign that the month-long structural reinforcement work may be coming towards its conclusion, and that longer term preparations for first flight are starting to get underway. The same fix to the upper wing stringers, which involves between four and five modifications per unit, has been installed on the static test airframe ZY997 and will be taken through a test cycle to clear ZA001 for first flight – targeted for before year end.

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

Unanswered questions, cautious optimism define 787 wing fix

By Jon Ostrower on October 16, 2009

While the installation of the 787 wing fix continues, Boeing engineers have returned to the drawing board to redesign part of the reinforcement, FlightBlogger has learned.

As a result, company and industry sources say the 2009 first flight target could be in jeopardy as engineers work to redesign the fix for four remaining wing stringers.

Boeing declined to discuss the modifications, saying that the next opportunity for an update will come on October 21st during the company's third quarter earnings call. However, the company did reaffirm that "we will fly by the end of the year."

Internal schedules, say several program sources, initially targeted October 15th for ZA001's to return to ground operations with a first flight to follow roughly six weeks later, however the aircraft remains in the paint hangar as engineers work to complete the design and installation of the side-of-body reinforcement.

The structures in question are stringers 2 through 5, the shortest and highest load stringers positioned in the aft of the wing boxes. Each wing box has 17 stringers designated 2-18.

Program sources indicate that the initial fix design for stringers 2-5 did not meet certification margins in computer modeling.

One source familiar with the wing fix says that the solution will remain consistent with what Boeing originally envisioned, but adds that the reinforcements could vary in length and/or location.

In a message to program staff on October 12th, 787 vice-president and general manager, Scott Fancher indicated that the progress on the installation is paced by engineering development.

Fancher said, "we are making headway on the [side-of-body] modifications. Great progress being made on engineering releases by the design team. This allows us to continue with the installation of fittings on the initial airplanes. The pace of the modification is increasing and I am confident that this integrated team will lead the way to first flight"

The company is working day and night to install the modification deep inside the center wingbox and wing structure of the 787 test fleet.

Sources add that installation of the existing design is progressing well, with ZA002 and ZA004 rapidly catching up to ZA001 and ZY997 as the learning curve for the installation has already begun come down.

Once the installation is complete ZY997, the static test airframe will undergo full-scale testing of the reinforcement that Boeing hopes will validate the design, clearing the way for the 787 to fly.

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1) Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

Morgan Stanley downgraded its

recommendation on Boeing on Tuesday, fretting that technical problems

will push first flight of the 787 Dreamliner into 2010 and, more importantly, first delivery of the plane to the spring of 2011, according to a Wall Street Journal report.

Morgan Stanley cut its recommendation from equalweight to

underweight because of these concerns, negative cash flow for 2010,

"poor" aircraft order demand and the likelihood of negative earnings

revisions, The Journal said.

Boeing officials insisted as recently as Saturday

that the 787 was on track to fly this year. They have promised to give

more details on the program in Wednesday morning's earnings call.

http://blog.seattlepi.com/aerospace/archives/182616.asp

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1) Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1) Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1) Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1) Re: Boeing 787 (partie 1)

Re: Boeing 787 (partie 1)