Bonjour ! Et meilleurs voeux à tous !

Un petit tour du côté de Kinston, lieu ou Spirit a monté sa fabrique de composants CFRP pour Airbus ....

On parle beaucoup de la logistique, pas trop au point pour l'instant ... bon, 2-3 Antonov ont réglé le PB dans l'urgence !

Ca reste intéressant pour avoir une idée des cadences de livraison !

C'est d'ailleurs ce que je vérifiais ... l'avancement du MSN 001, aprés le "Statique"

Il semblerait bien que les pièces des 2 premiers, aient été (Ou sont en cours pour le 2nd envoi) reçues en 2011, c'est rassurant !

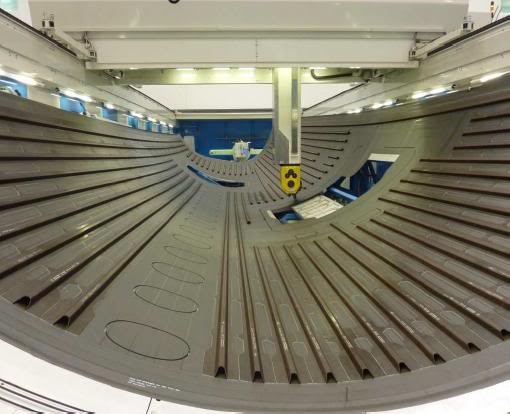

Les longerons des ailes ... on est en avance chez Spirit ! C'est bien, (Et moins bien côté GKN, qui ont eu des ennuis avec le rear spar, côté fixation du train)

Un "Set" par mois pour 2012 à venir, donc déjà plus que les pré-séries , 8 exemplaires de production sont possibles !

------------------- Le lien et des extrait de Kinston.com -------------

http://www.kinston.com/articles/keep-78621-little-aircraft.html

David Anderson

Staff Writer

In a little over a year, a full set of aircraft wing and fuselage components – broken into five shipments – has been shipped from Spirit AeroSystems’ Kinston plant,

and company officials plan to ramp up to one shipment a month in the coming year.It is a place officials with the Wichita, Kan.-based supplier of aircraft components planned to be by the end of 2011.

“

We expected to ship two units before the end of the year, and what Airbus has asked us to do is plan on and prepare to ship one unit per month (in 2012),” said Don Blake, director of quality and site services for Spirit’s Kinston plant.The Kinston facility, which opened in July of 2010 at the N.C. Global TransPark, was created to design, engineer and build wing and fuselage components for Airbus’ new A350 XWB passenger aircraft.

-------------

The sections of the wing spar were built and shipped first. The very first “production product” left Kinston via truck on Dec. 9, 2010.

“The wing products, or the wing components, are typically designed and constructed ahead of the rest of the airplane because it’s the most complex and the most important part, and so they want more time for design and test and construction,” Blake said.

The wing components have been trucked to the state’s ports at Morehead and Wilmington, and sent by container ship to Spirit’s manufacturing facility in Prestwick, Scotland, for final assembly, and then transported to Airbus’ facilities in Toulouse, France to be incorporated into the rest of the aircraft.

When put together, the spar is 102 feet long. After the first spar unit went out last December, a second one was shipped Aug. 22 and a third shipped Dec. 5.

The first fuselage panels went out Oct. 24 and were loaded onto a massive Antonov An-124, one of the largest cargo aircraft in the world. The panels were flown to another of Spirit’s manufacturing plants in St. Nazaire, France to be put together before being sent onto Airbus in Toulouse.

The containers needed to ship the 65-foot-long fuselage panels, are 20 feet wide and 12 feet tall, Blake explained.

While Spirit’s long-range logistical plan for Kinston is to ship fuselage and wing components by rail to the port at Morehead City, the first fuselage shipments this year went out by the cargo plane – on Oct. 24 and Dec. 4 – because Airbus wanted them before the Christmas holiday.

“These large freighters that were using, it can take multiple pieces of our units so that if we have units – if they’re done and they’re ready to go – we can put more than one unit on an airplane,” Blake said

JPRS